How to Build a Pallet Shed DIY for Storage: A Practical Solution

Constructing a pallet shed offers a cost-effective and environmentally conscious method for increasing storage capacity on one's property. This comprehensive guide details the process of building a durable and functional pallet shed, emphasizing practicality and attention to detail throughout the construction phases. While utilizing reclaimed pallets contributes to sustainability, careful consideration must be given to the selection and preparation of the pallets to ensure structural integrity and safety.

I. Planning and Preparation: Laying the Foundation for Success

Before commencing any construction, a thorough planning phase is crucial. This involves several key steps to ensure the project’s success.

A. Site Selection and Assessment

The first step involves selecting a suitable location for the pallet shed. Consider factors such as: accessibility (easy access for material delivery and future use), level ground (minimizing excavation and leveling requirements), sun exposure (to ensure proper ventilation and prevent moisture buildup), and proximity to utilities (if electricity or other services are required).

B. Pallet Acquisition and Inspection

Sourcing suitable pallets is paramount. Prioritize pallets made of pressure-treated lumber for durability and weather resistance. Inspect each pallet meticulously for damage, rot, or infestation. Discard any pallets exhibiting significant deterioration. Ideally, obtain pallets of consistent dimensions for ease of construction. The quantity of pallets required will depend on the desired dimensions of your shed.

C. Design and Dimensioning

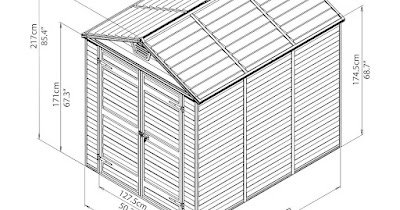

Develop a detailed plan outlining the dimensions of your shed. Consider the amount of storage space needed and the available site area. Simple rectangular designs are often the most straightforward for DIY projects. Create detailed drawings, including precise measurements for each component, to guide the construction process. This includes the shed's overall dimensions, door size and placement, roof pitch, and wall framing.

D. Material Gathering and Tool Preparation

Beyond pallets, you will require additional materials, including:

- Concrete blocks or a suitable foundation: For a stable base.

- Concrete mix or gravel: To level the foundation.

- Roofing material: Tarpaulin, corrugated metal sheeting, or asphalt shingles.

- Fasteners: Galvanized nails, screws, and possibly construction adhesive.

- Wood treatment: To protect the wood from the elements (optional but recommended).

- Tools: Hammer, saw, drill, measuring tape, level, shovel, safety glasses, gloves.

II. Construction Phase: Assembling the Pallet Shed

The construction process follows a logical sequence, starting with the foundation and culminating in the roof.

A. Foundation Construction

Begin by preparing a level base. This can involve excavating a shallow trench and filling it with gravel, creating a concrete slab, or simply using concrete blocks to create a stable platform. Ensure the base is level using a spirit level to provide a solid foundation for the pallet structure. The size of the foundation should correspond precisely to the planned dimensions of the shed’s base.

B. Pallet Wall Construction

Once the foundation is ready, start assembling the pallet walls. Begin with the longest walls first. This typically involves stacking pallets vertically, securing them together using screws and/or nails, and reinforcing the joints with additional wooden supports where needed. Ensure the walls are plumb (vertical) and square. You may need to cut and adjust some pallets to fit perfectly.

C. Door Installation

Construct a door frame using sturdy pallet boards or additional lumber. Cut a section from one of the pallet walls to create the doorway. Securely attach the door frame and then fit a suitable door. This may involve using salvaged pallet boards or purchasing a pre-made door. Reinforce the hinges and locking mechanism for added security.

D. Roof Construction

Construct the roof frame using sturdy pallet boards or additional lumber. Create a frame that is slightly wider than the shed’s width to ensure sufficient overhang to protect the walls from rain. The roof pitch should be steep enough to allow for proper water runoff. Attach the chosen roofing material securely. This could be a simple tarpaulin, corrugated metal sheets, or asphalt shingles depending on your budget and aesthetic preference. Ensure the roofing material overlaps sufficiently to prevent water leakage.

E. Finishing Touches

After completing the main structure, add finishing touches to enhance the shed’s functionality and appearance. Consider adding shelves or other internal storage solutions. Apply a wood treatment or sealant to protect the pallets from moisture and extend the lifespan of the structure. You could also add a layer of insulation if the shed is to be used in a climate with extreme temperature fluctuations.

III. Safety Precautions and Considerations

Safety should be paramount throughout the entire construction process.

- Always wear appropriate safety gear, including safety glasses and work gloves.

- Use caution when handling power tools. Ensure you understand how to operate each tool correctly and follow all safety instructions.

- Inspect pallets thoroughly for nails or staples that could cause injury.

- Securely fasten all components to prevent collapse or accidental injury.

- Ensure proper ventilation to prevent moisture buildup and mold growth.

- Obtain necessary permits before starting the construction, if required by local regulations.

IV. Conclusion: A Sustainable and Practical Storage Solution

Building a pallet shed offers a sustainable and cost-effective solution to storage needs. By following these guidelines and prioritizing safety, you can create a functional and durable structure. Remember that attention to detail in planning and construction will ensure a long-lasting and aesthetically pleasing addition to your property. The unique character of reclaimed pallet wood adds a rustic charm, transforming a simple storage solution into a visually appealing feature of your outdoor space.